What is better? D2 Steel or 440C Steel? - a detailed comparison

👉 The key facts from this guide

- D2 steel is hard and wear-resistant, but difficult to sharpen and can be brittle.

- 440C steel is flexible and corrosion-resistant, but less hard than D2.

- D2 is suitable for working knives and tools that require high hardness.

- 440C is ideal for outdoor activities as it is rustproof and tough.

- Both steels have similar hardness, but 440C is better protected against rust.

- The choice depends on your needs: D2 for hardness, 440C for flexibility.

Are you looking for a new knife and wondering which knife steel is the best?

The selection of the right steel is important because it determines the hardness, sharpness, and flexibility of your knife.

Two popular options are D2 and 440C steel.

Both have advantages and disadvantages.

In this article, you will learn everything you need to know to make the perfect choice for your application.

Which is better? D2 steel or 440C steel?

D2 steel is the better choice when maximum hardness and wear resistance are required. For flexible knives with high toughness, 440C steel is preferable due to its lower brittleness.

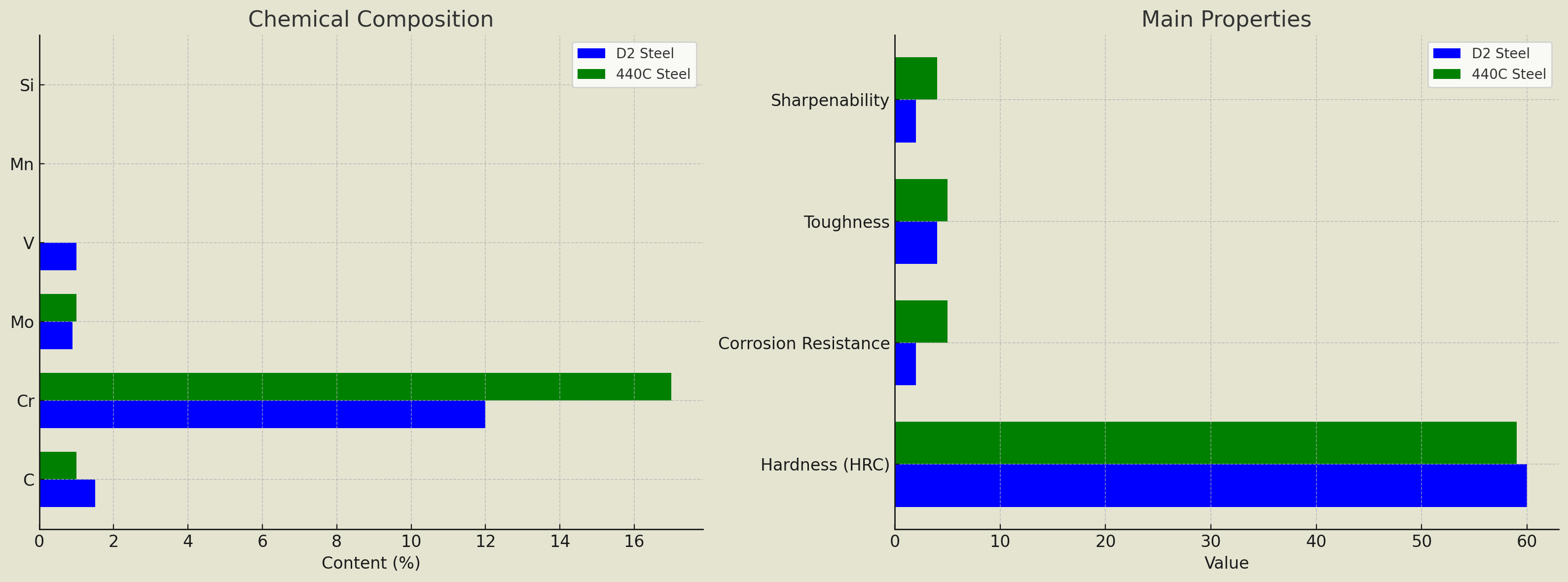

Here is a table comparing D2 and 440C knife steel:

| Property | D2 Steel | 440C Steel |

|---|---|---|

| Composition | 1.5% C, 12% Cr, 0.9% Mo, 1% V | 1% C, 17% Cr, 1% Mo |

| Hardness | 58-62 HRC | 58-60 HRC |

| Corrosion Resistance | Moderate (non-stainless) | Very high (stainless) |

| Toughness | High | Very high |

| Sharpenability | Difficult | Easy |

| Price | Lower | Higher |

| Advantages | - High hardness - Good wear resistance |

- Very corrosion resistant - Flexible and tough |

| Disadvantages | - Tendency to brittle fracture | - Lower hardness |

| Applications | - Utility knives - Cutting tools |

- Outdoor knives - Ball bearings |

Let us now delve deeper into the topic so that you choose the best steel for yourself.

What is D2 Steel? - hard, sharp, but brittle

D2 steel is a high-alloy tool steel known for its high hardness and wear resistance.

It belongs to the category of cold work steels and mainly consists of:

- 1.4 - 1.6% carbon

- 11 - 13% chromium

- 0.6% manganese

- 0.9% molybdenum

- 0.6% silicon

- 0.8 - 1% vanadium

These alloying elements give D2 steel its excellent properties, making it a popular choice for various applications.

In Germany, the steel has the special number 1.2379. Sometimes people also call the steel Böhler K110. Or they call it X 55CrVMo12-1.

Properties of D2 Steel

-

High Hardness: D2 steel has a hardness of about 58-62 HRC, making it one of the hardest steels on the market. This high hardness allows for excellent edge retention and wear resistance.

-

Good Corrosion Resistance: Although D2 steel is not stainless, it still offers good corrosion resistance compared to many other tool steels. Regular maintenance and oiling can further improve corrosion resistance.

-

High Toughness: Despite being very hard, D2 steel also offers good toughness. This means that it is not easily prone to breaking and has some impact resistance.

D2 is therefore ideal for heavy-duty applications where maximum hardness is required. This makes it popular for work knives in crafts and industry.

Applications of D2 Steel

-

Tool manufacturing: Due to its high hardness and wear resistance, D2 steel is often used for the production of tools that need to withstand high stress. These can be cutting tools, punching tools, or molds, for example.

-

Knife manufacturing: D2 steel is also frequently used for the production of knife blades. Its high hardness and edge retention make it one of the most popular steel types for knife enthusiasts and professionals.

The disadvantages of D2 steel

- Brittleness - D2 tends to be prone to brittle fracture. The blade can break or splinter under heavy load.

- Difficult to sharpen - The high hardness makes sharpening with simple tools challenging. Special sharpening steels are required.

For flexible outdoor knives, D2 knife steel is less suitable. The risk of breaking or splintering is too high.

What is 440C Steel? - tough, flexible, easy to sharpen

440C steel is a high-performance stainless steel known for its excellent corrosion resistance and toughness.

It belongs to the category of martensitic stainless steels and contains about:

- 0.95 - 1.2% carbon

- 16 - 18% chromium

- 1% manganese

- 0.75% molybdenum

- 0.04% phosphorus

- 1% silicon

- 0.03% sulfur

This alloy (the high chromium content) gives the 440C steel its unique properties and makes it one of the most popular knife steels for various applications.

The 440-C steel is also known in Germany as 1.4125, X105CrMoV17 and Böhler N695.

Properties of 440C Steel

-

Excellent corrosion resistance: 440C steel is one of the most corrosion-resistant steels on the market (low carbon content). It is resistant to corrosion, rust, and many aggressive chemicals. This makes it ideal for applications in damp and corrosive environments (such as stainless steel).

-

High hardness: 440C steel has a hardness of about 58-60 HRC, similar to D2 steel. This high hardness allows for good edge retention and wear resistance.

-

High toughness: 440C steel also offers good toughness, meaning it is resistant to breakage and deformation. This is particularly important for applications that require high-impact resistance.

As a result, 440C is particularly suitable for outdoor, hunting, and Survival Knives. The increased flexibility and toughness provide more safety during hard use.

Applications of 440C Steel

-

Knife production: Due to its excellent corrosion resistance (low carbon content) and hardness, 440C steel is often used for the production of high-quality knife blades. It is popular among knife makers and collectors worldwide.

-

Ball bearings: 440C steel is also commonly used for the production of ball bearings. Its high hardness and corrosion resistance make it an ideal choice for applications that require smooth rotation.

The disadvantages of 440C knife steel

- Lower hardness - The maximum hardness is lower than that of D2. The blade will dull faster. However, sharpening is easier.

For extreme stress or as tool steel, 440C is less suitable. The lower hardness sets limits here.

A suitable reading tip here:

Read also

Which steel is ideal for bushcraft knives? - 7 popular types of steel featured - How to choose the right steel for your bushcraft knife - A handy guide to take your bushcraft skills to the next level.

What is better? D2 steel or 440C steel?

Whether D2 steel or 440C steel is better depends on your specific requirements and preferences.

Both steels have their unique properties and advantages that make them suitable for various applications.

-

When it comes to hardness and wear resistance, both D2 steel and 440C steel are excellent options. Both steels have a similar hardness of about 58-62 HRC and offer good edge retention.

-

When it comes to corrosion resistance, 440C steel has a clear advantage. Due to its stainless nature, it provides excellent rust resistance, while D2 steel requires regular maintenance to avoid corrosion.

-

When it comes to toughness, both D2 steel and 440C steel offer good properties. Both steels are resistant to breakage and deformation, with 440C steel potentially having slightly higher toughness due to its martensitic structure.

Here I have another graphic for your overview:

Ultimately, the choice between D2 steel and 440C steel depends on the specific requirements of the application.

I advise you to assess the requirements and characteristics of your specific outdoor style and, if necessary, consult experts or professionals to make the best choice. However, both steels are usable for Bushcraft Knives, Survival Knives, and Pocket Knives.

Frequently Asked Questions (FAQs)

What is the difference between D2 steel and 440C steel?

D2 steel and 440C steel differ in their chemical composition and properties. D2 steel is a high-alloy tool steel (carbon steel) with high hardness and good wear resistance. 440C steel is a stainless high-performance steel with excellent corrosion resistance and toughness.

Which steel is harder, D2 or 440C?

Both D2 steel and 440C steel have a similar hardness of about 58-62 HRC. It is difficult to determine a clear winner in terms of hardness, as both steels are very hard.

Which steel is more corrosion resistant, D2 or 440C?

440C steel is more corrosion resistant than D2 steel. D2 steel is not stainless and requires regular maintenance to prevent corrosion. On the other hand, 440C steel is stainless and offers excellent corrosion resistance.

Which steel is better for knife blades, D2 or 440C?

D2 steel and 440C steel are both popular options for knife blade manufacturing. D2 steel offers high hardness and wear resistance, while 440C steel exhibits excellent corrosion resistance and toughness. The choice depends on the user's individual preferences and requirements.

Can D2 steel or 440C steel be sharpened?

Both D2 steel and 440C steel can be sharpened. However, due to their hardness, they may be slightly more difficult to sharpen than softer steels. I recommend using high-quality sharpening stones and the proper sharpening tools to achieve optimal results.

Which steel is pricier, D2 or 440C?

The price of D2 steel and 440C steel can vary depending on the supplier and availability. In general, 440C steel is slightly pricier than D2 steel because it is stainless and offers better corrosion resistance.

Also read

What are the common knife grinds for outdoor knives? (How to choose the right outdoor knife) – Learn everything about the most important knife grinds for your outdoor knife. This way, you will find the optimal grind for each activity such as carving.

Conclusion: The choice depends on you and your requirements

The choice between D2 steel and 440C steel depends on the specific requirements and preferences.

Both steels have their unique properties and advantages that make them suitable for various applications.

D2 steel offers high hardness and wear resistance, while 440C steel exhibits excellent corrosion resistance and toughness.

With the right care and maintenance, both D2 steel and 440C steel can deliver excellent performance and bring you years of joy.

Author of the guide

Martin Gebhardt

Hey, I'm Martin. On my blog, you will learn the basics and numerous details about living in the wild. I think survival, bushcraft and the good life in nature are the keys to happiness. Find me here on Instagram or on YouTube. You can find more about my mission on the About Me page.

Since this is a gear guide, here ...

🤝8 reasons to trust my recommendation

-

Practical Experience: I have tested most of the products I recommend under extreme conditions myself.

-

Independence: As a wilderness mentor, I am not tied to any specific brands - this means my recommendations are unbiased.

-

Expertise: My many years of experience allow me to understand the intricacies and details of various products that a layperson might overlook.

-

Target group understanding: I understand the needs and challenges of outdoor enthusiasts, from beginners to seasoned experts.

-

Quality focus: I attach great importance to quality and longevity. These are characteristics that are crucial in the wild.

-

Clear communication: I try to explain the pros and cons of each product clearly and understandably so that you can make an informed decision.

-

Currentness: I always keep my guides up to date and adapt them to new findings or products.

-

Community Feedback: I work in wilderness schools, teach courses myself, attend courses and am active in various outdoor and survival communities and therefore integrate the feedback and experiences of others into my recommendations.

So when I introduce the best survival knives or flashlights, you can be sure that every recommendation is based on solid experience and extensive knowledge.

Was this guide helpful?

31 people found this guide helpful.

5.00 out of 5 points (31 Ratings)

Comments (0)

This post may contain affiliate links. So if you click on the links and make a purchase, I will receive a small commission at no additional cost to you. Click here, to learn more about it.